Advanced CNC Machining Capabilities for High-Quality Parts and Components

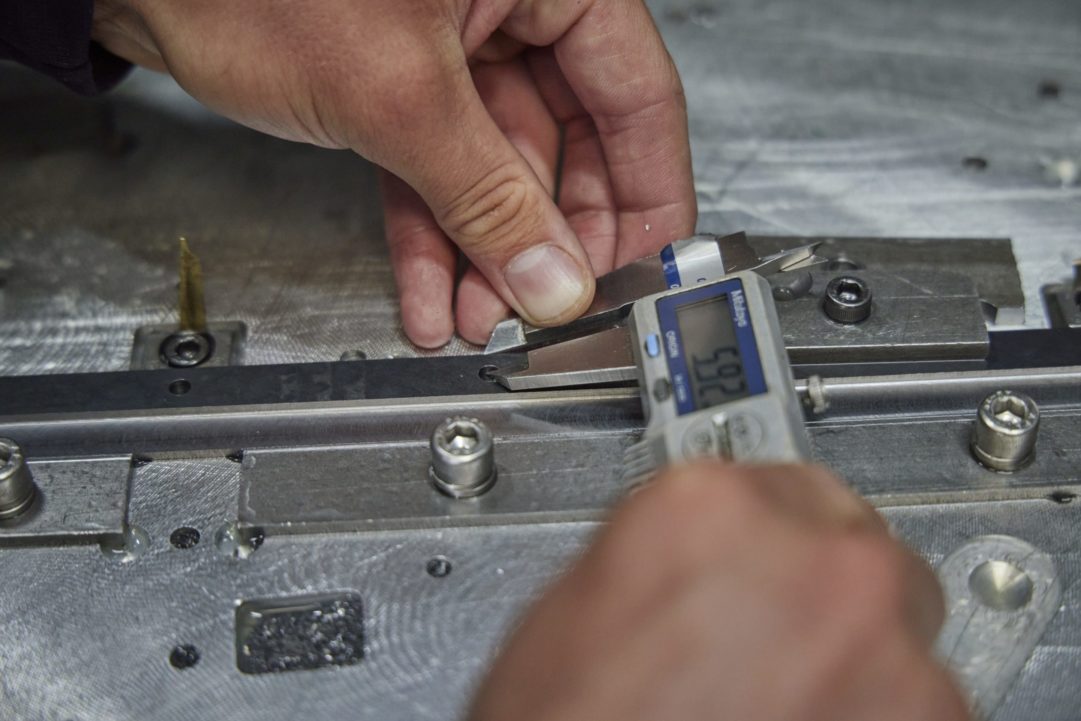

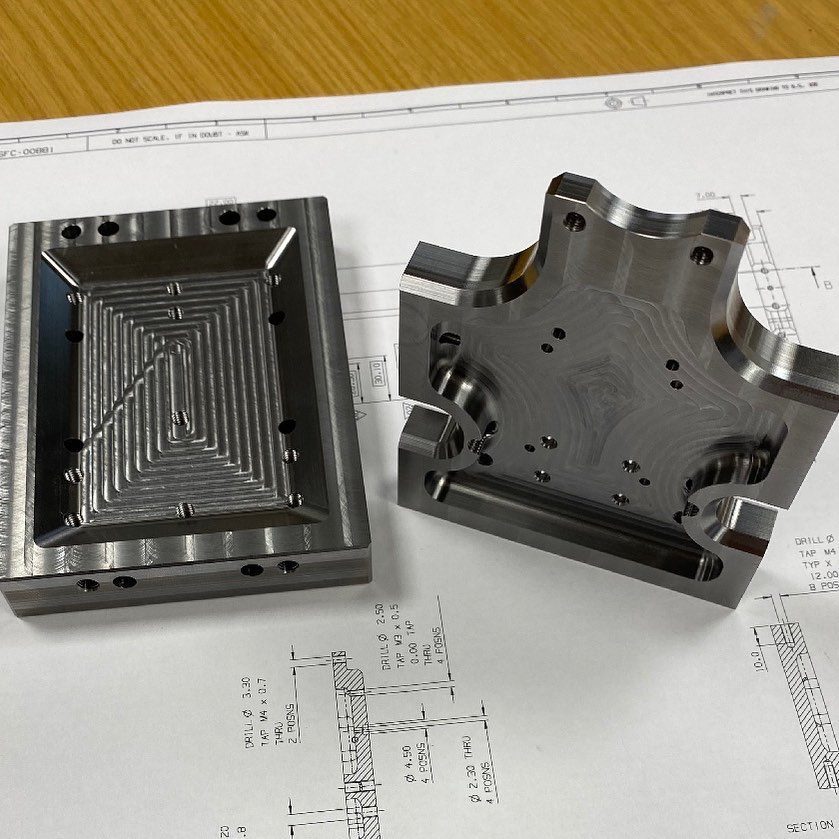

Kenworth Engineering offers a wide range of advanced CNC machining capabilities to produce high-quality parts and components to your exact specifications.

Our state-of-the-art machinery and experienced operators enable us to offer a range of CNC machining services, including 5-axis milling, 3-axis milling, mill/turn, production turn, sliding head turn, and centre lathe turn.

Whether you need rapid prototyping, small-batch runs, or large-scale production, we have the expertise and technology to deliver the highest standards of accuracy, precision, and reliability.

Our team is committed to providing the best possible CNC machining solutions for your project, so contact us today to learn more about how we can help.

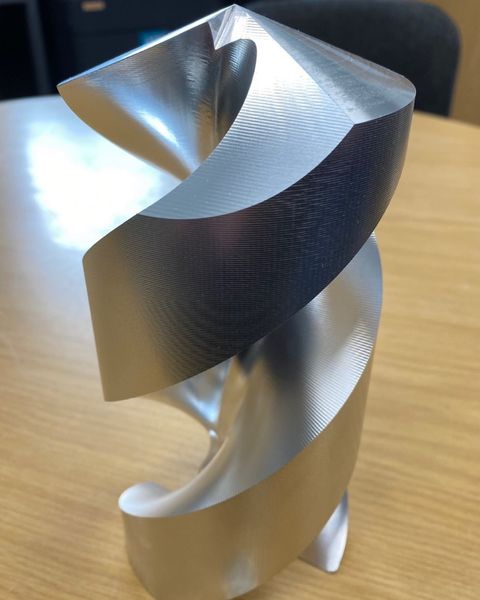

5-axis Milling Capabilities

Components up to 600mm in diameter

3-axis Milling Capabilities

Components up to 1200mm long, 600mm wide and 600mm high.

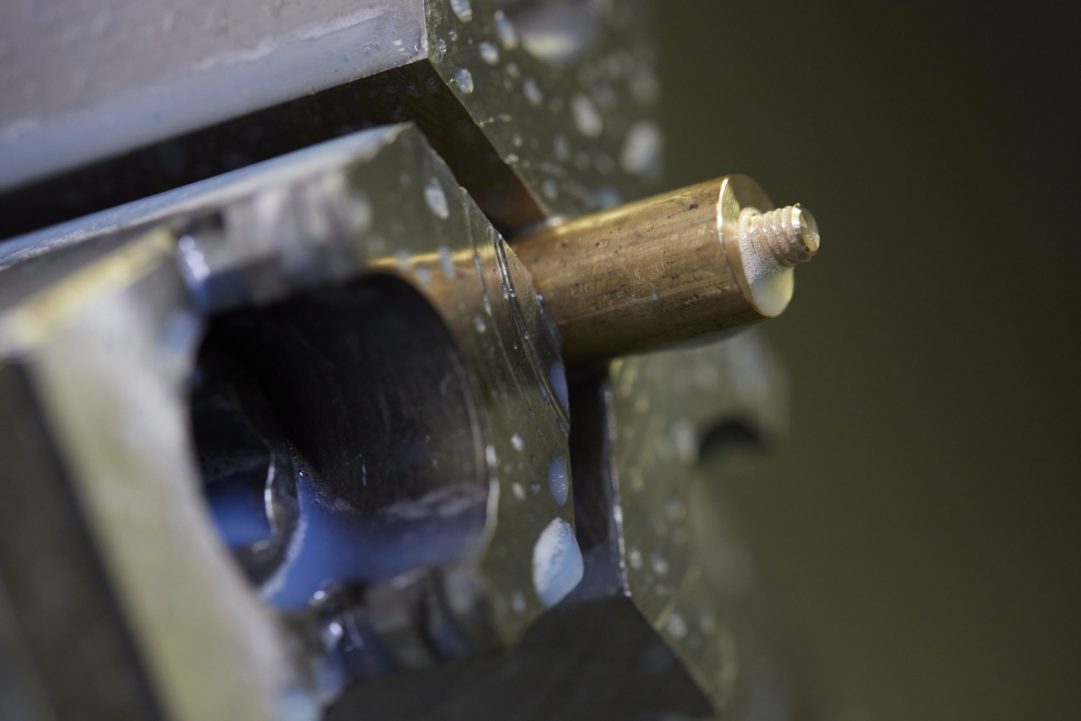

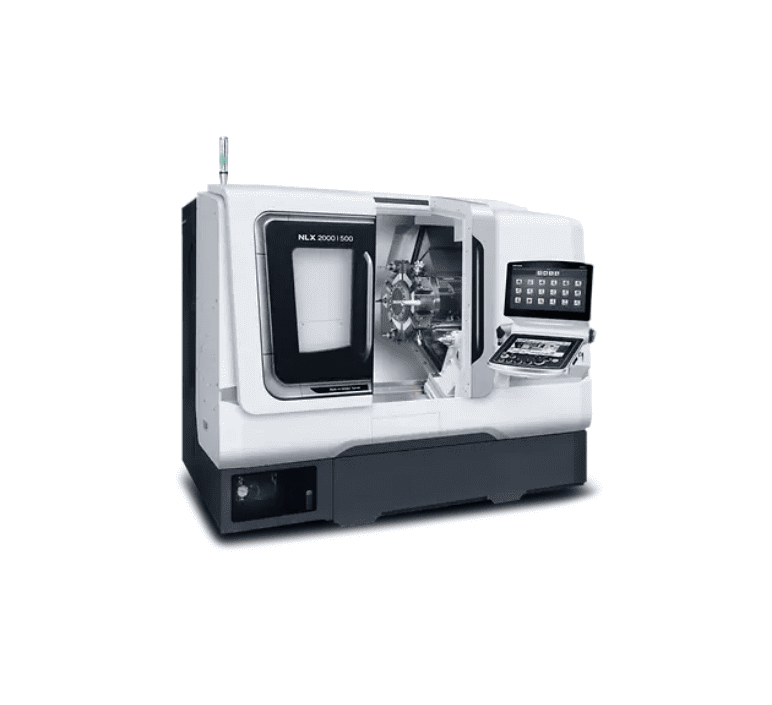

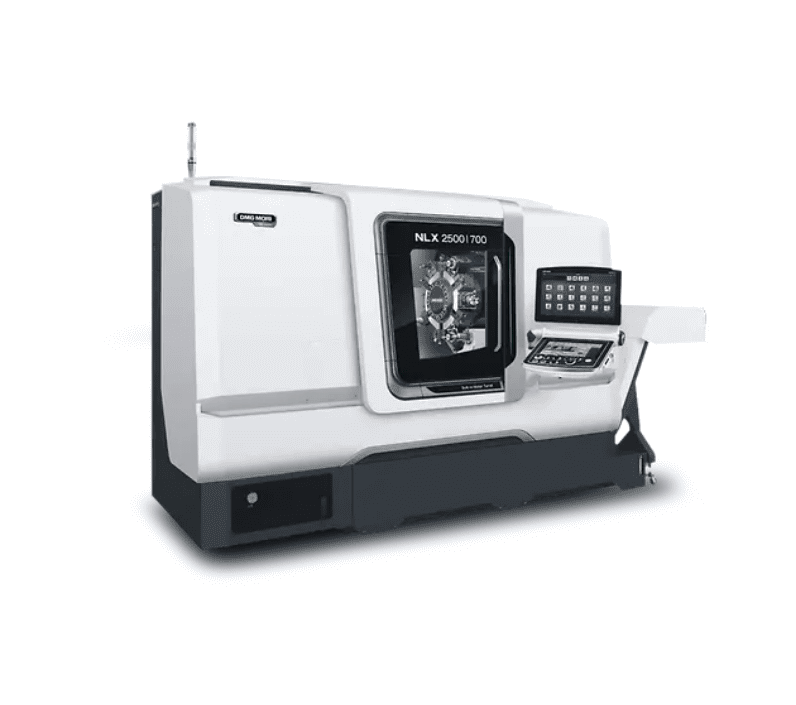

Mill/Turn Capabilities

Components up to 300mm diameter and 700mm in length.

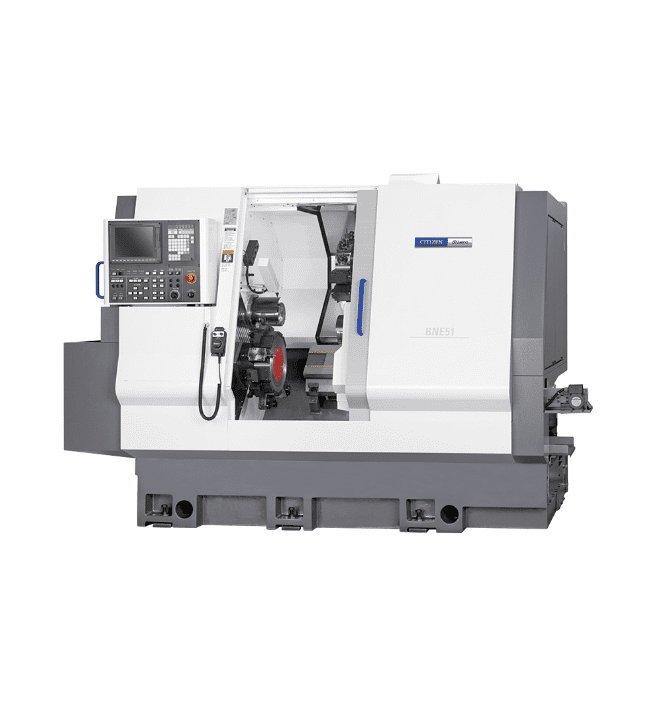

Production Turn Capabilities

Components up to 51mm diameter and 100mm in length.

Sliding Head Turning Capabilities

Components up to 22mm diameter and 150mm in length.

Centre Lathe Turning Capabilities

Components up to 200mm diameter and 1500mm in length.

Get your quote today