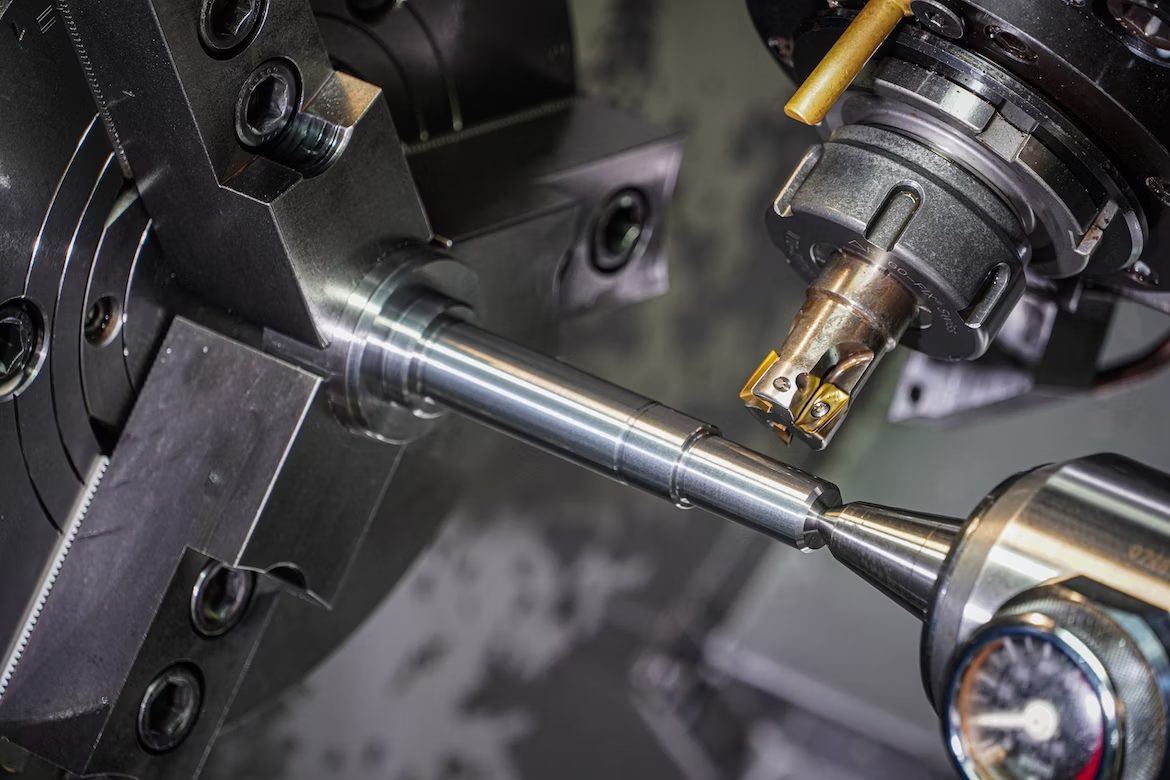

CNC machining is a precise and efficient manufacturing process that involves the use of computer-controlled milling and turning machinery to create parts and components to tight tolerances and specifications.

Choosing the right material for your project is essential in order to achieve high-quality results in CNC machining.

We’re going to explore the factors that need to be considered when selecting a material for CNC machining, the different types of materials commonly used in CNC machining, and provide best practices for material selection.

Factors to Consider in Material Selection

When selecting a material for CNC machining, there are several factors that need to be considered.

Material properties, machinability, cost, availability, and environmental considerations are all important factors that can impact the material selection process.

For example, materials with high strength and hardness are often preferred for parts that will be exposed to high stresses or wear. On the other hand, softer materials that are easier to machine may be preferred for parts with complex shapes or tight tolerances.

Types of Materials Used in CNC Machining

There are several types of materials commonly used in CNC machining, including metals, plastics, and composites.

Each material has its own strengths and weaknesses, and may be best suited for certain types of applications.

Metals such as aluminium, stainless steel, and titanium are often used in CNC machining due to their strength, durability, and corrosion resistance.

Plastics such as ABS, polycarbonate, and nylon are often preferred for their low weight and ease of machining.

Composites such as carbon fibre and fibreglass offer high strength-to-weight ratios and are often used in aerospace and automotive applications.

Best Practices for Material Selection in CNC Machining

To ensure the best possible results in CNC machining, it is important to follow best practices for material selection.

Consider the application

The first step in material selection is to consider the application of the final product. What conditions will it be exposed to? What performance characteristics are required? This information can help you determine which materials will be best suited for the job.

Evaluate material properties

Different materials have different properties that can affect their performance during machining. Factors like hardness, strength, and ductility can impact the cutting tools and processes used in machining, so it’s essential to select a material that is compatible with the machining processes being used.

Consult with experts

Consulting with experts in material selection can help you choose the right material for your project. They can provide insights into the properties of different materials and advise you on the best choices for your application.

Optimise design for manufacturing

Designing parts with manufacturability in mind can help ensure that the material is used efficiently and that machining is as cost-effective as possible.

Conclusion

In conclusion, material selection is a critical factor in achieving high-quality results in CNC machining. By understanding the different factors to consider when selecting a material, the types of materials commonly used in CNC machining, and best practices for material selection, you can ensure the success of your own CNC machining projects.

Looking for a reliable CNC machining partner who can guide you through the material selection process? Kenworth Engineering has years of experience and a reputation for delivering high-quality results for both CNC turning and CNC milling operations. Contact us today to learn more.