If you’re looking for a complete guide to everything CNC turning then you’re in the right place. We’re going to take a deep dive into what CNC turning is, how it works, the history of metal turning, and the benefits of this manufacturing process.

What is CNC?

CNC stands for Computer Numerical Control and is used in manufacturing processes to direct machine tools to create parts and components using a computer that has been programmed with tool directions and paths from a CAD file.

CNC is used to control a wide range of machines including lathes, mills and turning centres and can produce far more accurate results than manual methods of machining.

CNC has also enabled far more automation within workshops. Where manual machining methods require constant input from an engineer, CNC machines, once programmed and set up can be left to get on with the manufacturing based on the program set by the engineer. Allowing computers to operate the machinery also helps to negate human error that can be made in manual machining operations.

So what came before CNC turning? Let’s take a brief tour of history to find out more.

A history of metal turning

The early days of turning

Metal turning hasn’t always been done using CNC and dates back to as long ago as the ancient Egyptians long before computers were even a thing!

Archaeologists have discovered evidence within tombs dating back to the 4th century showing people operating ancient lathes.

It is thought that the ancient Egyptians used two wooden posts that held a spindle in place with a rope strung around it that was used to create the spinning motion required. They would spin raw material in the form of wood on this ancient lathe and sand it down to the required shape and form.

As time progressed, somewhere around the middle-ages, so too did the turning process. Instead of using a bow or a rope to spin the material, which required hands to do, a pedal was introduced which freed up the hands of the worker allowing them to use their feet to control the spinning motion.

Turning in the industrial revolution

With the dawn of the industrial revolution came advances in engineering. Lathe machines began to be powered by steam, and later we’re motor-driven, opening up far greater possibilities for this process.

Digital revolution

As the ’60s and ’70s swung in, so too did digital technology. Before CNC we had NC, or Numerically Controlled machines.

NC was first pioneered by John T. Parson in the 1940s and became the go-to process for manufacturing parts and components for the US Airforce. NC allowed for far greater accuracy and allowed more complex parts to be machined much easier, and more importantly, cheaper.

NC used a set of cards which had a program that contained the positioning information for the tools. These codes were called G-Codes. NC had many drawbacks that CNC sought to solve.

G-code is still the programming code used today but is now controlled by computer systems, hence the C in CNC.

The metal turning process continues to get better year after year with companies eager to find even more efficient ways to manufacture products for their customers.

As demands increase for precision parts, with far more complex parts and components being required by industries across the world, CNC turning has become the go-to method for many manufacturing companies.

What is CNC Turning and how does it work?

CNC turning is a manufacturing process that uses computers to control the tools within CNC lathes and turning centers to create parts and components as per the specification of the design.

The use of CNC processes results in far more accurate products than manual methods and with increased automation of the process, greater consistency and efficiency in workshops has been found and only continue to get better.

The CNC turning process works by rotating bars of raw material such as metal, plastic or composite materials at high speed using a CNC lathe machine.

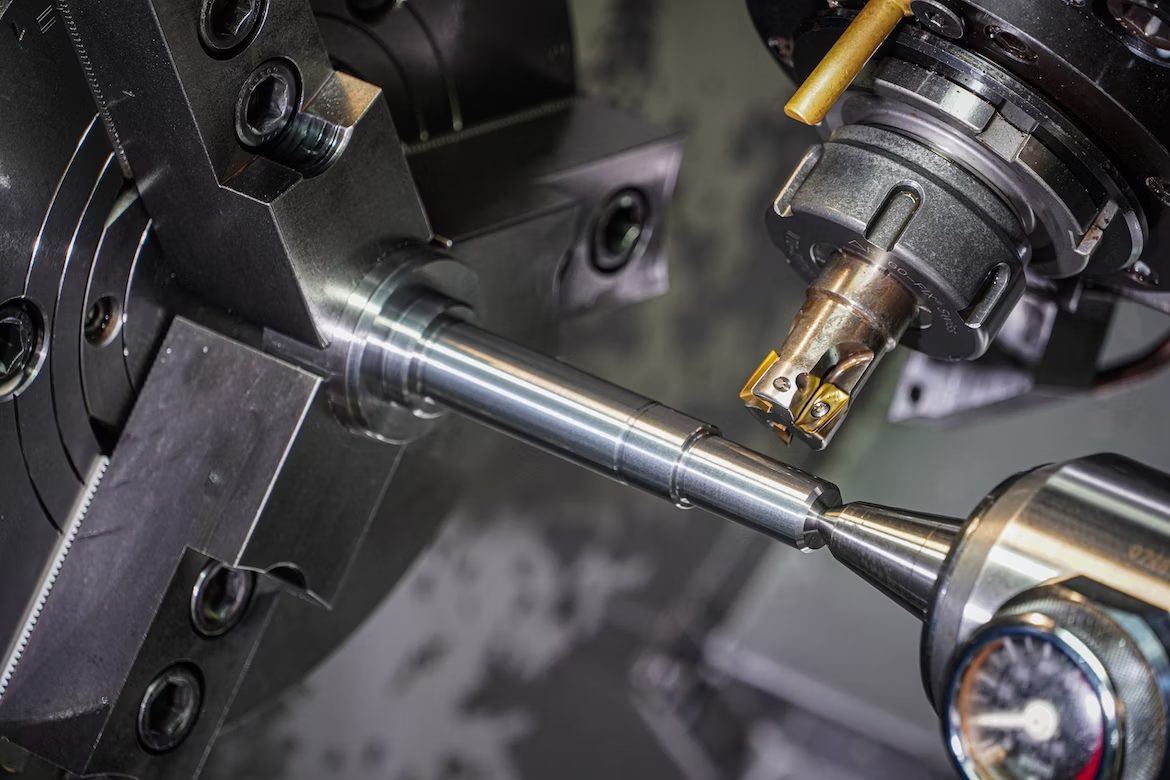

The material is held in place by a chuck which rotates on the main spindle, with the cutting process seeing machine cutting tools being fed into the machine across various axes that works the base material into the desired shape and form.

This type of machining process is known as a subtractive machining process where the cutting tools remove material from the base material until it forms the final machined part.

CNC turning differs from other types of machining processes as it is the material itself that spins instead of the tooling.

Modern CNC machines can be fitted with bar feeder technology which allows the base material to be consistently fed into the machine to be cut by the tooling, thus greatly increasing the productivity and efficiency of this machining process.

The CNC turning process involves many complex operations which we will look at in turn in the next section.

CNC Turning Operations explained

There are various types of turning operations that can be carried out on CNC lathe and turning centre machines, all of which have different use cases that are dependent on the design of the part to be machined. Each machine operation will have its own unique tooling which will be decided upon based on the design and specifications required.

Let’s take a closer look at the various turning operations and why and when they are used.

Step turning

Step turning is used to create two or more surfaces with a defined difference in diameter. This forms a step in the workpiece similar to a staircase.

Taper turning

Taper turning is used to create a uniform tapered shape in the workpiece and works by moving the cutting tool at an angle to the axis of the workpiece. The diameter of the workpiece will change from one end to the other with the tapering being able to go in both directions, inside and out.

Chamfer turning

Chamfer turning creates a smooth angled edge that transitions between two steps in the workpiece that differ in diameter.

Contour turning

Contour turning is used to create smooth curved geometries with different diameters in a workpiece. The cutting tool follows a predefined path to create the desired contours.

Facing operations

Facing is used in the machining process to create parts to a specified length. The cutting tool will move along the radius of the workpiece removing material until the part is set to the specified length leaving a smooth surface.

Grooving

Grooving uses a specific groove-cutting tool that is moved into the side of the rotating workpiece cutting a groove into the material. There are two types of grooving operation: External and face grooving. The groove size will all depend on the size of the cutting tool and may need multiple operations to create the desired groove size.

Parting

Parting is where the material is cut into separate pieces, usually at the end of a turning process. The cutting tool will work perpendicular to the workpiece and will create a cut in the material until it reaches the centre of the workpiece, at which point, the separated piece will fall off, usually into a part catcher.

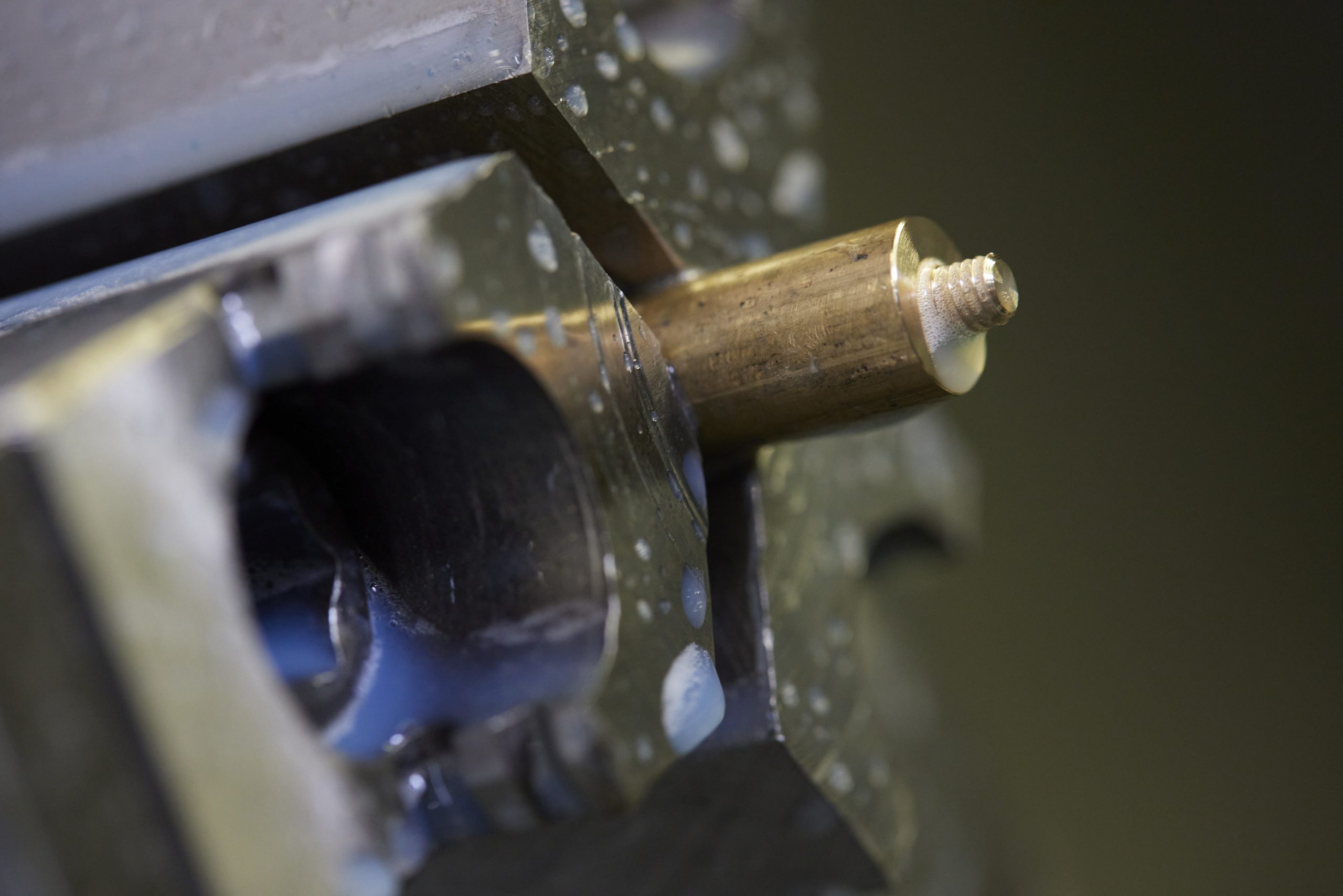

Threading

The cutting tool moves along the edge of the rotating workpiece and cuts grooves known as threads into the material. A thread is a helical groove with specific depths and lengths between each thread.

Knurling

Knurling operations create patterns on a workpiece, usually in a diamond formation. A knurling tool is used that contains serrated teeth on its surface which make an impression on the material as it works on the side of a workpiece.

Knurling is typically used to create more grip on parts and components and also for aesthetic reasons.

Drilling

Drilling operations create holes in the workpiece, removing material from inside the base material to form holes. Drill bits of various sizes can be utilised to create holes of differing diameters.

Reaming

Reaming is generally used after a drilling operation to make the diameter of a drill hole larger. Reaming can also be used to create smoother finishes inside the hole than can be obtained from drilling alone.

Boring

Boring uses a boring tool and is used to remove material from inside the workpiece. Boring can be used to create various shapes within a workpiece or to enlarge pre-drilled holes

Tapping

Tapping operations are used to create internal threads inside a pre-drilled hole in a workpiece. Think of the nut to a bolt.

CNC programming

So, what is CNC programming and how does it work?

CNC programming is the process of creating a set of instructions that will tell a CNC machine how to create a specific part. The instructions are written in a language called G-code (remember this from an earlier section? G-code has been around since the 1960s and is still in use today!) which is a text-based language that can be interpreted by a CNC machine.

G-code consists of a series of commands that tell the machine how to move its tools, how to apply cutting and shaping tools to the workpiece, and how to control the speed and direction of the cut.

To create G-code instructions, you first need to design the part you want to create using a CAD program.

Once the design is complete, an engineer uses CAM (computer-aided manufacturing) software to convert it into G-code instructions. CAM programs can be used to create simple or complex parts, and they can also be used to create toolpaths that will allow you to create more intricate shapes and patterns.

Once the G-code is created, it is then loaded into a CNC machine controller, which will then interpret the code and direct the machine to create the desired shape for your parts or components. The controller will also monitor the status of the machine and make any necessary adjustments to ensure that the part is being created accurately.

Benefits of CNC Turning

The benefits specific to CNC turning processes are: high accuracy, repeatability, and consistency; the ability to process a wide range of materials; the ability to produce parts with complex shapes; and the ability to achieve very tight tolerances.

CNC turning operations can also be largely automated meaning that reductions in costs due to labour requirements can be found easily. Automation leads to much more efficient and speedier manufacturing and can massively reduce the chances of things going wrong due to human error.

CNC Turning is best if you are looking to create fast and repeated symmetrical or cylindrical parts with a high production volume. CNC Turning can produce parts of high quality and an extremely smooth finish.

Common problems with CNC Turning and how they are avoided

As with anything, there can be drawbacks and issues that are common, but choosing the right CNC machining company will ensure that many of these issues will be addressed and have measures in place to ensure they don’t cause problems with a project.

Improper tooling or settings

Selecting the wrong type of tool for the job, or using tools that are not in good shape can be an issue.

Using tools that are not sharp or damaged will hurt the overall quality of the finished part. Poor surface finish or cutter marks can easily be left in the material if the wrong tool or damaged tools are used.

Using improper coolant or lubricant, or running the machinery at incorrect speeds can also be detrimental to the overall finish.

Experienced machine shops and engineers will already know this and will ensure that the correct tools, quality tools and correct setup are prepared before starting a job.

Programming errors

Whilst the CNC program will handle everything to do with the job, the program first needs to be created by an engineer.

Incorrect programming can happen even by experienced programming engineers – we’re all human after all.

One of the main ways of ensuring the program is correct before beginning production is by running the program through a simulation process. This allows the engineer to ensure the program works before working on the machine.

Test runs are also undertaken to ensure the program works before full production begins. Any issues in the program can then be ironed out before production.

Poor machine maintenance

To keep machines running efficiently and accurately they need to be properly maintained and serviced.

This means keeping the machines serviced as per their servicing requirements set out by the manufacturer as well as keeping them properly clean and maintained.

Good workshops will adhere to the service schedules and clean and lubricate the machine between jobs to ensure it runs optimally.

Chatter or vibration

Chatter or vibration in a CNC lathe can cause issues when it comes to the quality of the parts being manufactured. Issues such as this will negatively affect the accuracy of the machine and can lead to parts being manufactured out of tolerance.

This issue is easy to spot by experienced engineers as the machine will vibrate or make undesirable noises.

Chatter and vibration are usually caused by unbalanced tooling or high spindle speeds, but these issues are quickly addressed by experienced operators.

CNC Turning or Milling? Which one is best for your project?

The choice between milling and turning will be determined by quite a few factors. In some cases, both processes will be required in order to achieve the final machined product you need.

Typically, milling is better suited to more complex shapes and geometries whereas turning is best suited to more simple round, cylindrical or conical shapes.

CNC Turning Centers – a hybrid between CNC turning and milling

CNC turning machines are becoming increasingly better year after year and one of the biggest advances in turning machine technology is in CNC turning centres.

These machines are a hybrid between conventional CNC lathes and CNC milling machines and allow for a wider range of possibilities than milling and turning machines can offer alone.

A CNC turning center is fitted with live tooling that is fed into the machine using a tool turret. This allows multiple tools to be preset in the machine, with the CNC program dictating which tool should be used at the right stage of the process.

CNC turning centers also have additional axes that are not present on standard lathe machines. This is similar to milling machines where it is common to have 3, 4 or even 5 axes of movement.

What types of materials can be used in CNC Turning?

Metal, plastics and composite materials are ideal for CNC turning as per the specification of the parts you require manufacturing.

Learn more about choosing the right material for your CNC machined parts in our recent guide

What things are typically manufactured using CNC Turning machines?

CNC turning can be used to manufacture many different kinds of parts and components including, but not limited to, shafts, nuts and bolts, rollers, nozzles, beams and pipes, barrels

Kenworth Engineering has a wide range of CNC machines including lathes and turning centres and can handle almost any requirement. We have over 30 years of engineering knowledge and are ready to take on your next turning project. If you require a precision CNC turning service partner, Kenworth Engineering should be your first port of call.

Speak to us today about how we can help you with your CNC turning requirements.