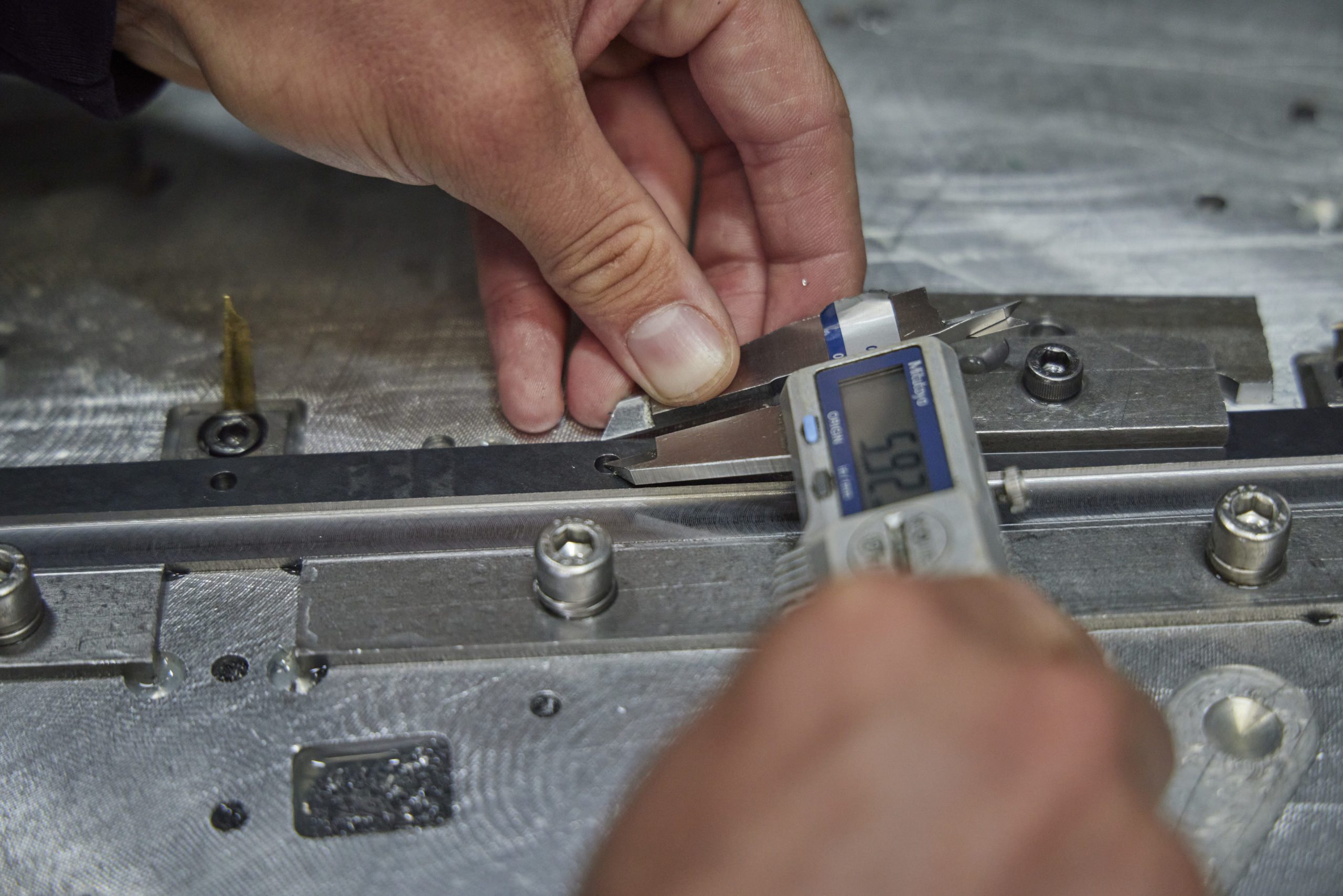

Discover Our Advanced CNC Milling Capabilities

Kenworth Engineering is proud to offer a comprehensive range of CNC milling capabilities to cater to the diverse needs of our clients. With state-of-the-art machinery and highly skilled engineers, we are equipped to handle various projects with precision, efficiency, and reliability. Explore our CNC milling capabilities below:

5-Axis Milling Capabilities

Our advanced 5-axis milling machines enable us to manufacture components with complex geometries and tight tolerances. We can accommodate parts up to 600mm in diameter, making this technology ideal for producing intricate designs in a single setup, reducing lead times and ensuring a high level of accuracy.

3-Axis Milling Capabilities

For larger components, our 3-axis milling capabilities allow us to produce parts up to 1200mm long, 600mm wide, and 600mm high. This versatile technology is perfect for a wide range of applications, from simple parts to more complex structures, all while maintaining the highest standards of precision and quality.

Mill/Turn Capabilities

Combining the best of both CNC milling and turning, our mill/turn capabilities offer exceptional flexibility and efficiency. We can handle components up to 300mm in diameter and 700mm in length, ensuring that we can meet the diverse needs of our clients across various industries.

Choose Kenworth Engineering for your CNC milling requirements and experience the benefits of our industry-leading capabilities and commitment to excellence.

Get your quote today